Mass customization promises to liberate the production process from the seasonality of collections and at the same time freeing the whole fashion chain from the “stock” risk, supplying tailor-made footwear to clients. “Now is the time”.

By Roberto Procaccini

Time and technology. Synchronization and infrastructure. Andrey Golub, ceo of ELSE Corp, make a consideration regarding mass customization. “Competencies to do so were already there”, speaking the Italian footwear industry, he says from his Italian office in Milan, Amendola neighbourhood, where young minds are developing the future of shoes.

Two aspects were missing: the first was technological support, because it wouldn’t have made sense to talk about 3-D printing and VR visualizers to clients “when within the chain designs are still done on paper in two-dimensions”; and, for this reason, the “demand on the market side” was missing from consumers and brands.

It was impossible to do it before, but one would be late if he/she started now. “Mass customization – smiles Golub -, now seems to be a common idea, but just five years ago it was the frontier”. 43 years old, a degree in applied mathematics, doctorate in research and artificial intelligence, master’s degree in business administration at Politecnico di Milano. The founder of ELSE Corp. knows that the time-factor is what determines the success of projects such as his. At the same time, software and hardware platforms now available are destined to change the time of fashion. “Let’s be honest, the fashion system is historically fixed on two collections per year – he states -, because the process from drawing to production, passing through the prototyping phase, took time and imposed this rhythm”. This mechanism has now transformed: “With CAD designs, virtual creation of models and Cloud sharing – adds Golub -, partners within the chain, brands, suppliers, manufacturers and others can share information in real time, thus saving money and time”.

It is an advantage for everyone, ensures Golub: “The business model that has been used till now. has foreseen that brands would bet on the public’s desires – he explains -. Production was followed by distribution and the eventual success of sales came after that.

With mass customization, on the other hand, it is possible to delay production based on market demand. With this capacity even the luxury segment, which is slow by definition, can become competition for fast fashion”.

ELSE Corp’s ceo wants to point out how: he isn’t talking about bespoke, but rather the personalization of shoes on industrial base. “We started working on the fashion industry in 2013, when we were working on a project with the goal of normalizing the sizes for the production of coats”, he says. The focus moved towards footwear, initially centered on the experience the store offered (ELSE is in fact an acronym for Exclusive Luxury Shopping Experience). “But we noticed right away how fundamental it was to solidify the production process – states Golub -, because it is impossible to offer a customization service if the entire product process isn’t aimed towards that goal. Everything, from warehouse to retail, must be engineered”.

Service remains focused on high-end goods at the moment, because “the operation is complex and costly, most of all with regards to the management of materials”, admits Golub. The extension of this methodology to other segments will be possible when the right warehouse operations’ systems will be created, “but I imagine it will involve the usage of additive synthetic materials – concludes Golub – while I am not sure about how much leather there will be “.

Custom Shoes

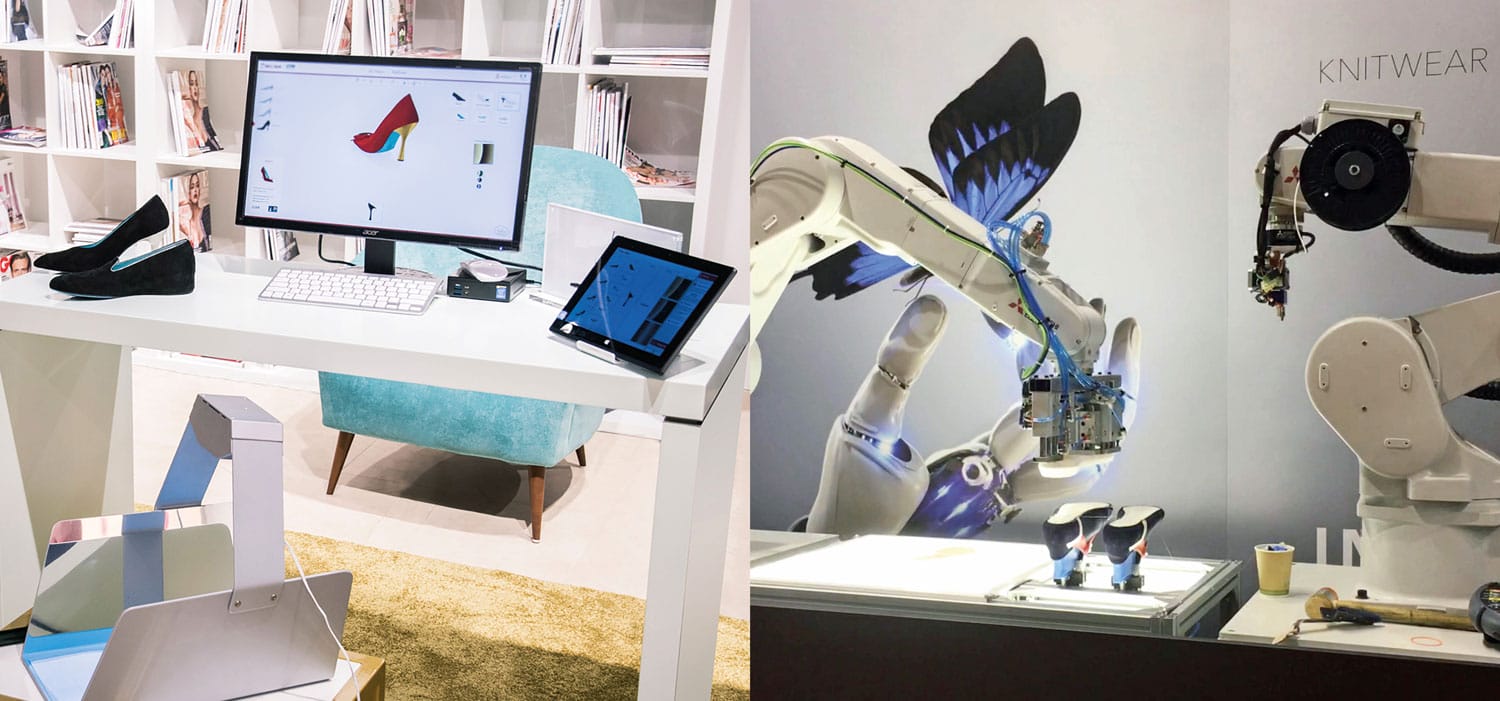

Everything starts from the store. Here the customer finds a scanner that measures dimensions and shape of the individual’s feet. Then, the client works on a screen where he can select the technical and esthetic options for the footwear, while the final result is shown in real time thanks to a projected 3-d image. The customer is helped with the choices by an artificial intelligence program, as well as a person on staff holding a tablet. Meanwhile, the sample materials and decorations allow consumers to get a real idea of what one can only imagine on the screen. “Customer assistance is very important – highlights Golub -, because the excess of choices could end up scaring off and intimidate the customer”. While the retail side is clear of stock-related risks, clients earn 3 levels of customization with ELSE, including the possibility to adapt the shoes to the characteristics (and peculiarities) of one’s feet.

The Story of ELSE Corp

Founded in Milan in 2014, ELSE Corp took its first step as a startup inside PoliHub, incubator of Politecnico di Milano. The company’s story, as recognized by its founder, changes in 2016, when the startup meets Atom, Italian manufacturer of machinery leader in the production of cutting machinery. With Atom, ELSE was able to extend its interests to the process before retail, focusing on footwear. And it is with Atom that ELSE, in 2018, created the joint venture project called Else Tech.