A tanning process that takes all the time necessary to reach the set quality standards. Since Giorgio Armani opened the debate, with the now historic letter to WWD, on slow luxury, the theme is a must in the fashion system. Incas answer with Slow Leather.

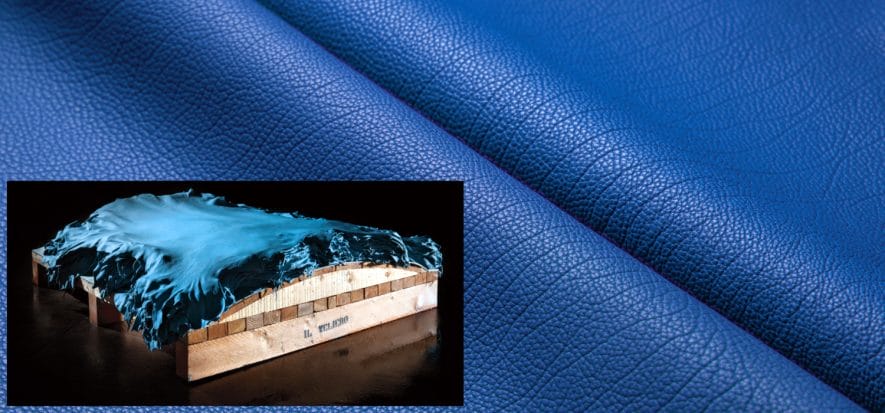

The production process from Il Veliero division “recovers the slowness of the tanning traditions against the modern conformism of speed – communicates the Tuscan company -, combining it with the most modern industrial techniques for a top-of-the-range product, with a low environmental impact”.

Incas answer with Slow Leather

Slow Leather is a chrome production process, which respects “the long maturation times of the hides – as explained by Incas, the only tannery to boast ICEC’s 100% made in Italy certificate -, with positive effects both on the quality of the produced and on the reduction of polluting waste”. To the principle of patience, let’s call it this way, “we add a series of tricks and innovations that guarantee the best sustainability standards”.

For example? “Starting from the acquisition of raw hides, Incas only uses certified companies that guarantee the traceability of the product right from the slaughterhouse – they continue -, but it is above all in the soaking and liming phases that one of the distinctive elements of Slow Leather is expressed”.

Post-tanning rest

From Tuscany, they illustrate the secrets of the Slow Leather process: “Through a system of containment tanks and sediments – states the note -, it is possible to recover more than half of the sulphide bath used for hair removal, returning it to the liming drum with a concentration of amines that guarantee leather an effect of fullness and roundness. All with saving 53% of water and 32% of sodium sulphide”.

After that, it’s time to rest. “After the tanning phase, the hides are left for at least 90 days in a dedicated environment”. Thus, “the chromium salts continue their action on the hides, so as to obtain a full and elastic finished product. The slowness of this process, called olation, allows to reduce the quantity of unsecured chromium that ends up in the wastewater generated by the subsequent pressing phase”.

The finish

Incas’ Slow Leather process also requires a lot of care in the finishing phase. “The recent adoption of HVLP (High Volume Low Pressure) technology for all spraying lines allows a significant reduction in the products used. Therefore, emissions into the atmosphere, without the use of fluorinated resins, xylene and tetrachloroethylene – the note concludes -, already banned even before the entry into force of the current legislation”.

Read also:

- The 40075-Line allows Incas to explain its take on metal free

- Anti-Covid certification: Incas tannery receive it first

- ICEC Anti-Covid certification: the number of companies is increasing