The opening of the new headquarters in Montorso Vicentino. Obtaining the Ecoleathers certification, issued by ICEC. “A fundamental piece within the development strategy of the company, in which we have invested and through which we have refined the production process”. These are the words of Alberto Caneva, Faeda’s CEO, a Venetian tanning group which, despite a problematic situation to say the least, is proceeding firmly along its upgrading process.

Upgrading Faeda

Inevitably, Caneva says, “2020 was a year of slowdown. The forecasts are however optimistic: once we get out of the pandemic tunnel, hopefully in the second half of next year, we expect a strong reaction from the market, with a strong push that will affect demand coming, in particular, from the leather goods and footwear sectors, which suffered the most during 2020”.

The certification

In Faeda’s growth path, Ecoleathers certification, issued by ICEC, the Quality Certification Institute for the Tanning Industry, will play a fundamental role. Faeda is among the very first tanning groups in Italy to obtain a certificate concerning “two different kind of products for leather goods and footwear for which it covers the entire production process – explains Caneva -.

However, as well as obtaining the certification, we had already implemented a series of monitoring processes aimed at controlling the environmental impact of our activities”. This is a strategic certification, which represents “an added value relating to a theme, sustainability, which is arousing interest in different customers – continues Caneva – as evidence of how it is a fundamental issue for everyone. As more and more it will be”.

UNI 11427

“The product certification of leather with reduced environmental impact (“ecoleathers” or “ecological leathers”) is based on the UNI 11427 standard – explains Sabrina Frontini, ICEC director -. It allows the company to communicate to its customer that the minimum product requirements have been met.

But also the minimum environmental requirements of the production process (for any type of tanning) foreseen by the standard to be able to call (real) ecological leather, ecoleathers or similar terms”. And, she confirms, the ICEC certification is in great demand by the main players active in the fashion field.

The new headquarters in Faeda

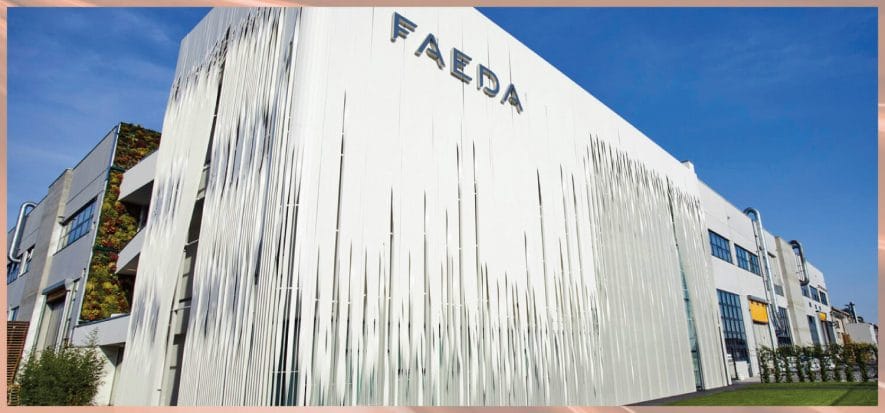

The opening of the new headquarters is part of the path undertaken by the Faeda Group. And at the same time, it represents “a point of arrival for the path made in recent years, and a starting point for what Faeda wants to become in the future”. The production site occupies a total area of 30,000 square meters. It uses a latest generation photovoltaic system that generates up to 140 Kwh, partially guaranteeing its energy self-sufficiency.

While the remaining part of the energy requirement is guaranteed by a cogeneration system. “Looking at the entire production complex from the outside – as explained by Faeda – you can also visually understand the different steps of growth undertaken, testifying to the different phases in which the recent history of Faeda has developed. At one end the original factory, acquired in 2012 and deliberately kept with its original appearance. At the opposite end, the large white facade accompanied, behind it, by a green wall, like a sort of vertical garden”.

Read also: